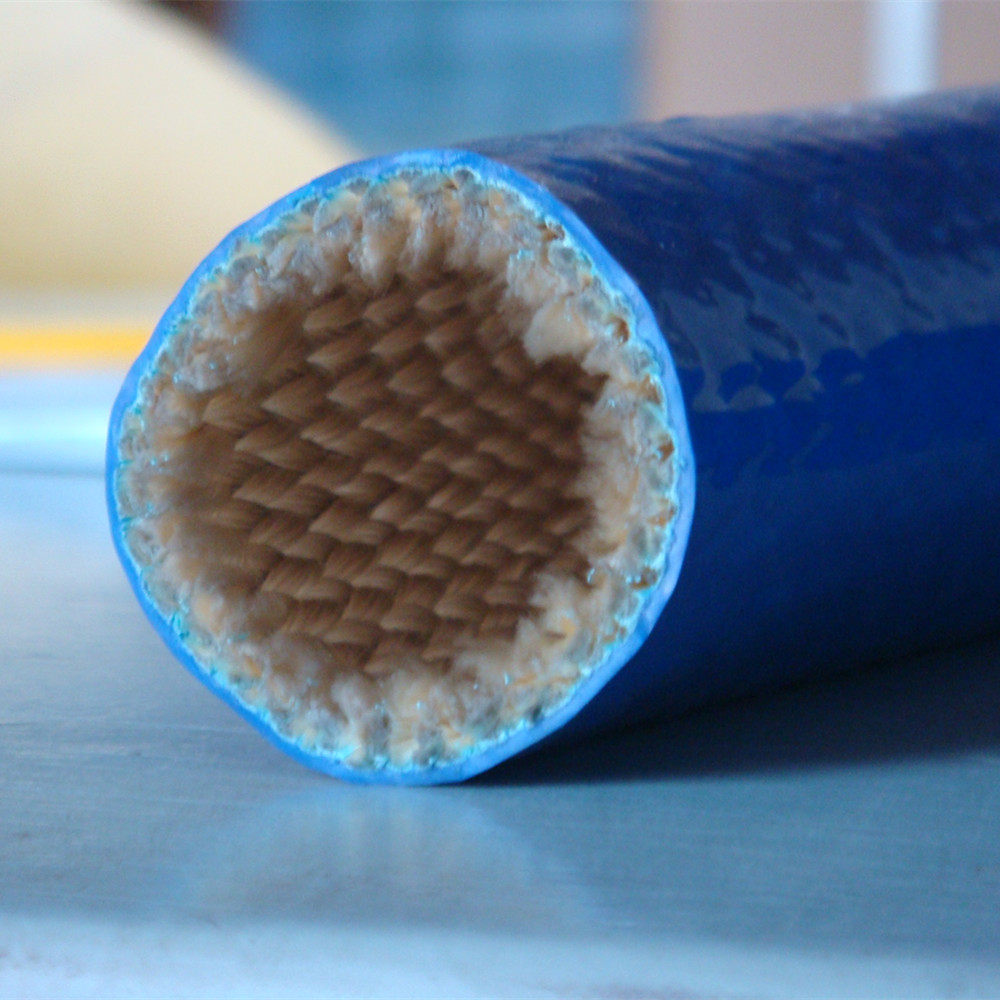

L'utilisation principale d'un manchon coupe-feu enduit de silicone est de protéger les tuyaux, les câbles et les fils des températures extrêmes, de l'exposition aux flammes et d'autres conditions environnementales difficiles. Voici quelques applications spécifiques :

Protection incendie : Le manchon fournit une barrière contre les flammes et les températures élevées, ce qui est crucial dans les environnements sujets aux incendies. Il aide à prévenir la propagation du feu et à protéger les composants sensibles des dommages causés par la chaleur.

Isolation thermique : elle isole les composants couverts de la chaleur extrême, maintenant l'intégrité et les performances des tuyaux, câbles et fils dans des environnements à haute température.

Résistance à l'abrasion : Le revêtement en silicone offre une protection contre l'abrasion, l'usure mécanique et la déchirure, ce qui prolonge la durée de vie des composants recouverts.

Résistance chimique : le manchon résiste à de nombreux produits chimiques, huiles et solvants, offrant une couche de protection supplémentaire dans les environnements chimiquement difficiles.

Isolation électrique : Dans certaines applications, le manchon sert également d'isolant électrique, empêchant les risques électriques et améliorant la sécurité.

Systèmes hydrauliques et pneumatiques : il est couramment utilisé dans les systèmes hydrauliques et pneumatiques des applications industrielles et automobiles pour protéger les tuyaux et les câbles de la chaleur et du feu.

Applications marines et aérospatiales : le manchon est également utilisé dans les industries marines et aérospatiales où l'exposition à des températures extrêmes et aux risques d'incendie est une préoccupation importante.

Dans l’ensemble, les manchons coupe-feu enduits de silicone sont essentiels pour garantir la sécurité, la durabilité et les performances des composants critiques dans des environnements exigeants.