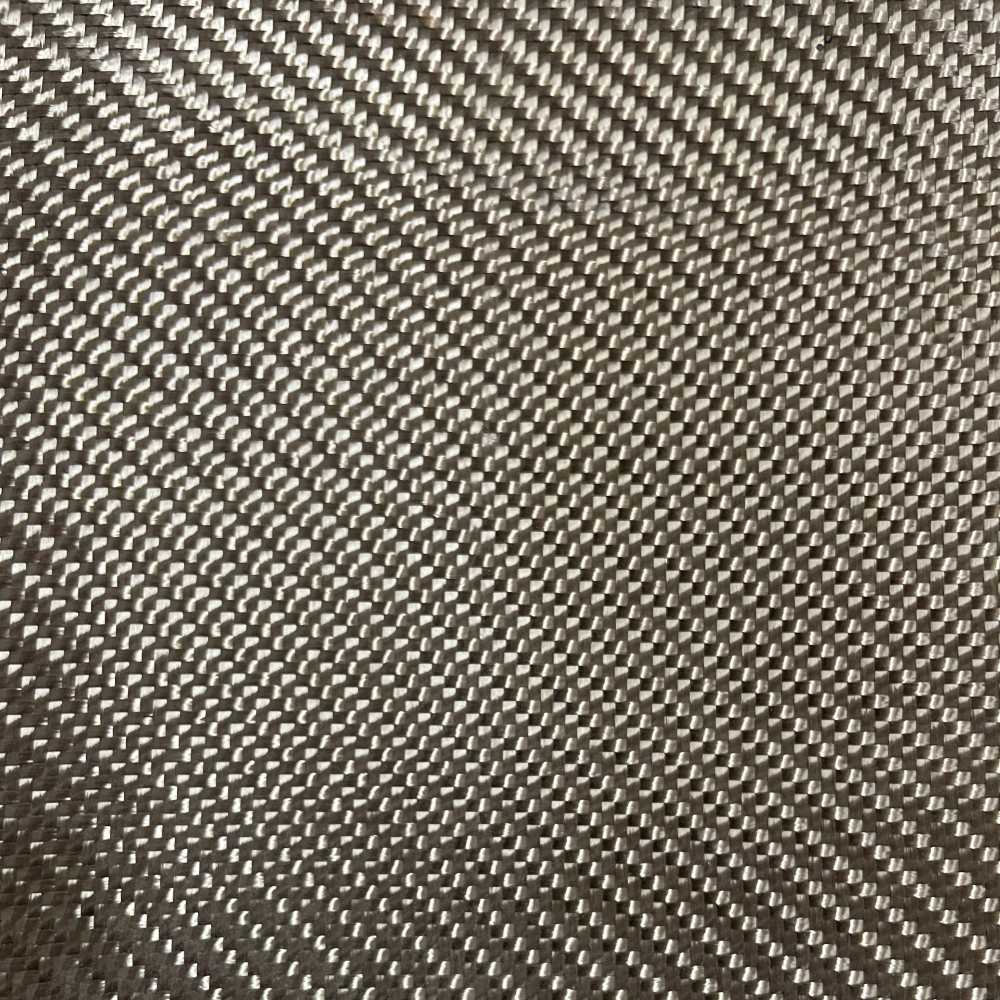

Le tissu en fibre de basalte, conçu à partir de roche volcanique de basalte, offre des caractéristiques de performance inégalées qui en font un matériau incontournable pour une variété d'applications industrielles exigeantes. Sa combinaison unique de propriétés de résistance thermique, mécanique et chimique le rend très efficace dans les environnements où la durabilité et les performances sont essentielles. Voici comment le tissu en fibre de basalte peut améliorer les performances et prolonger la durée de vie des composants dans les environnements industriels :

L’une des caractéristiques les plus remarquables du tissu en fibre de basalte est sa capacité à résister à des températures extrêmes sans perdre son intégrité structurelle. Capable de supporter des températures continues jusqu'à 1 000 °F (538 °C) et de résister à de courtes rafales jusqu'à 1 500 °F (815 °C), c'est un matériau très efficace pour :

Dans les environnements industriels à haute température tels que les aciéries ou les centrales électriques, le tissu en fibres de basalte agit comme une barrière thermique robuste, aidant à prévenir les dommages causés par la chaleur aux machines et réduisant le risque de défaillance thermique.

Le tissu en fibre de basalte présente une résistance à la traction et une résistance impressionnantes à l'abrasion, aux chocs et à la déchirure. Cela en fait un excellent choix pour les applications nécessitant une grande durabilité, telles que :

Sa haute résistance mécanique lui permet de résister à l’usure des conditions industrielles difficiles, assurant ainsi une durée de vie plus longue aux composants qu’il protège.

Dans les environnements industriels où l’exposition aux produits chimiques et aux substances corrosives est courante, le tissu en fibre de basalte excelle. Il reste insensible à la plupart des acides, alcalis et solvants, ce qui le rend adapté à une utilisation dans :

En résistant à la dégradation chimique, le tissu en fibres de basalte réduit le besoin de remplacements fréquents, réduisant ainsi les coûts de maintenance et améliorant l'efficacité opérationnelle dans des environnements corrosifs.

Malgré sa résistance robuste, le tissu en fibre de basalte est léger et flexible, ce qui le rend facile à installer dans des systèmes industriels complexes. Cette facilité de manipulation le rend idéal pour envelopper ou renforcer des composants dans des espaces restreints ou des formes complexes, tels que :

La légèreté contribue également à améliorer les performances dans des secteurs tels que l'aérospatiale et les transports, où la réduction du poids est un facteur clé du rendement énergétique et des performances globales du système.

Le tissu en fibres de basalte agit également comme un isolant électrique efficace, ce qui le rend adapté aux applications où la conductivité électrique doit être minimisée. Cette propriété améliore son utilisation dans :

En fournissant une isolation thermique et électrique, le tissu en fibres de basalte contribue à améliorer la sécurité et les performances des systèmes électriques dans les opérations industrielles.

La fibre de basalte est un matériau naturel et écologique produit à partir de roches volcaniques abondantes, offrant une alternative durable aux fibres synthétiques. Son processus de production respectueux de l’environnement, combiné à sa durabilité, en fait un matériau clé pour les industries cherchant à réduire leur empreinte environnementale.

Même si le tissu en fibre de basalte peut avoir un coût initial plus élevé que certains matériaux traditionnels, ses avantages en termes de performances à long terme se traduisent par des économies de coûts significatives. Sa durabilité, sa résistance à la chaleur, aux produits chimiques et à l'usure mécanique réduisent considérablement le besoin de remplacements et de réparations fréquents, contribuant ainsi à réduire les coûts d'exploitation et de maintenance au fil du temps.

Le tissu en fibre de basalte révolutionne les applications industrielles en améliorant la durabilité et les performances dans une variété de secteurs. Sa résistance à la chaleur, sa durabilité chimique, sa résistance mécanique et sa légèreté inégalées en font un matériau idéal pour protéger les composants critiques, réduire les besoins de maintenance et optimiser les opérations industrielles. Qu'il soit utilisé dans l'isolation haute température, les revêtements de protection ou le renforcement structurel, le tissu en fibre de basalte améliore à la fois les performances et la longévité dans les environnements industriels les plus exigeants.